Valve Cases

Valve Cases

- waj

- china2

- Information

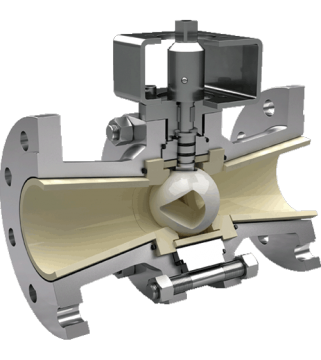

CERAMIC LINED BALL VALVES

Conventional valve materials cannot meet the demands of all industrial applications. Where they fail, high-performance ceramic materials open up new opportunities. Ceramics prove to be beneficial wherever standard materials reach their limits with respect to wear resistance, corrosion, and high temperatures.

CERA SYSTEM is the leading technological pioneer in industrial valves and pipe components with ceramic linings.

HARDNESS & WEAR RESISTANCE

Abrasion from entrained solids in liquids, high viscosity slurries, pneumatic conveying, and many other demanding services can drastically reduce the life of most traditional valve styles.

Lined valves utilizing ceramic materials that exhibit hardness values substantially higher than most metals can maximize the life of the valve.

FEATURES & BENEFITS

SOLID CERAMIC INTERNAL PARTS

CERAVALVE utilizes only solid ceramic internal valve parts (no coatings)

Ceramic liners are a minimum of thick for ultimate protection against abrasion

The ceramic components protect the entire flow path from valve inlet to outlet

Founded in Guangzhou in 1991, it now has more than 300 employees and a R&D and manufacturing base with a construction area of 54000m2; Over the past 30 years, we have focused on metal connection technology, independently developed the core technology of intermediate frequency inverter DC and medium voltage capacitor energy storage resistance welding, introduced advanced riveting technology, and formed a complete metal connection process; The products cover a full range of resistance welding and rivet free riveting, planar self piercing riveting equipment, as well as automatic production lines for washing machines, dishwashers, ovens, refrigerator compressors, and liquid storage tanks; Serving automotive body manufacturing.

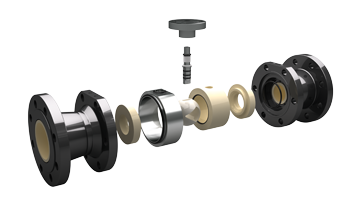

MODULAR DESIGN

1 Several flange and body size combinations are available to meet specific application requirements

2 A wide range of Cv values are available to meet various control applications

3 Simplified spare parts allow for easy on-site valve maintenance

DESIGN OPTIONS AVAILABLE

Floating and trunnion mounted ball versions

High temperature versions

Various body and ceramic liner/ball material options

Low emission shaft sealing available for strict environmental requirements

MODULATING (CONTROL) VALVE VERSIONS

Reduced Bore Design

Improved throttling of medium

Smaller valve ball reduces overall valve cost

Maximum opening angle reduces wear on internal valve parts